TL;DR: A screw-driven home lift moves on a fixed steel screw using a rotating nut, which makes it self-locking and prevents free fall. Typical UAE installed price is AED 80,000–250,000. It fits tight spaces with 0–50 mm pit, needs ~2300–2500 mm headroom, runs quietly at ~40–60 dB, and installs in ~5–15 days. Best for 2–6 stops in villas where safety, reliability, and easy retrofit matter more than speed (~0.15 m/s).

This guide is for affluent homeowners, property developers, and architects in the United Arab Emirates who are evaluating home lift options for new or existing villas. Here, you will gain a complete, expert-level understanding of screw-driven technology, a detailed comparison against its alternatives, transparent cost breakdowns for the UAE market, and a step-by-step process for making a confident and informed investment in your property. If you’re weighing lift technologies for a home lift in UAE, this guide explains costs, permits, and safety before we dive into why screw-driven lifts stand out.

What is Screw-Driven Home Lift?

A screw-driven home lift is a vertical transportation system that utilizes an electric motor to rotate a large drive nut. This nut is threaded onto a stationary, threaded steel bar (the screw). As the nut rotates, it travels up or down the screw, smoothly and securely moving the attached lift platform between floors.

Self-locking screw

A self-locking screw is a specific engineering design of the screw-and-nut mechanism where the angle of the screw’s thread creates a level of friction high enough to prevent the lift from moving downward under its own weight. The lift can only descend when the motor actively rotates the nut, ensuring an inherent and powerful layer of mechanical safety.

Evidence Snapshot

The following table provides key benchmarks for screw-driven home lifts within the UAE market, establishing a data-driven foundation for your decision-making process.

Table 1: Screw-Driven Home Lift - UAE Benchmark Data

| Metric | Typical Range / Value |

|---|---|

| Total Installed Cost (UAE) | AED 80,000 – 250,000 |

| Typical Speed | 0.15 m/s |

| Maximum Travel Height | 10 – 20 metres |

| Maximum Stops | 2 – 6 stops |

| Required Pit Depth | 0 – 50 mm |

| Required Headroom | 2300 – 2500 mm |

| Operational Noise Level | ≈40 – 60 dB |

| Typical Installation Time | 5 – 15 days |

The data presented here illustrates a technology profile that is not just suitable but perfectly optimized for the luxury low-rise residential sector. While the speed of 0.15 m/s is slower than commercial elevators, it is more than adequate for a two-to-four-story villa, where the journey between floors is short. More importantly, the specifications for minimal pit depth, low headroom, quiet operation, and rapid installation directly address the primary concerns of homeowners considering a retrofit: minimizing disruption, preserving the home’s structural and aesthetic integrity, and ensuring a peaceful living environment. The technical limitations in speed and height are, in this context, features that define its suitability for its specific, high-value niche.

How Do Screw-Driven Home Lifts Work? The Core Mechanism Explained

Understanding the engineering behind a screw-driven lift is key to appreciating its inherent safety and reliability. Unlike more complex systems, its brilliance lies in its mechanical simplicity, a technology originally developed and perfected in Sweden, a country with a global reputation for safety-focused engineering.

The Simple Genius: Screw, Nut, and Motor

Understanding the engineering behind a screw-driven lift is key to appreciating its inherent safety and reliability. Unlike more complex systems, its brilliance lies in its mechanical simplicity, a technology originally developed and perfected in Sweden, a country with a global reputation for safety-focused engineering.

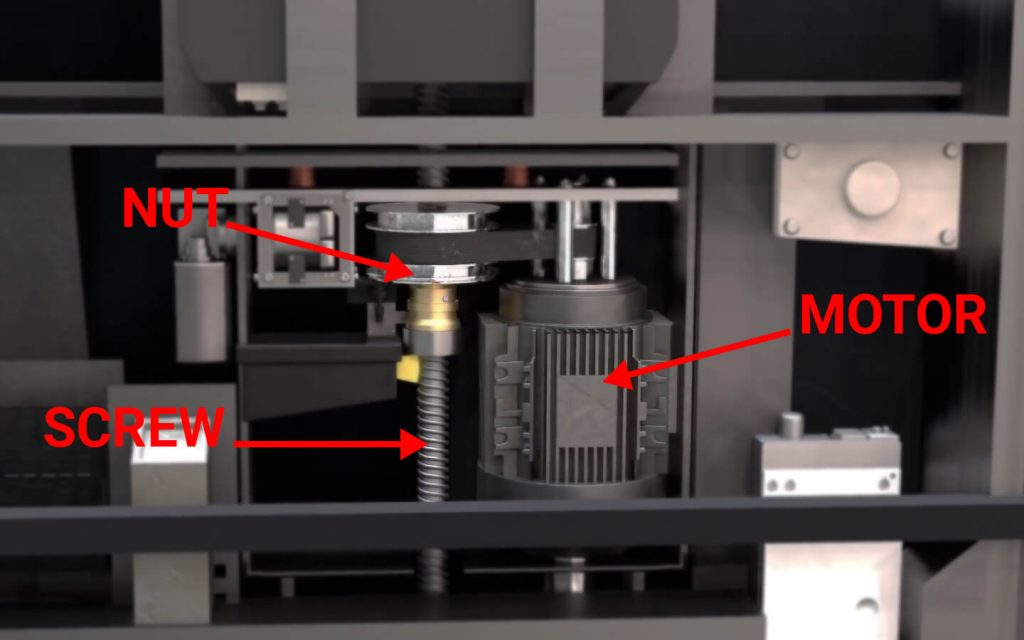

Labeled close-up of the Cibes screw-driven system showing the screw, drive nut, and motor.

At the heart of the system is a straightforward and robust principle. Imagine a giant, stationary threaded steel bar (the screw) that runs the full height of the lift’s travel. A large drive nut is threaded onto this screw and is securely attached to the lift cabin. A high-efficiency electric motor is connected to this nut. When a button is pressed on the control panel, the motor turns the nut in one direction, causing it to climb the screw and lift the cabin. When the motor turns in the opposite direction, the nut travels down the screw, lowering the cabin smoothly and precisely.

This direct-drive system is elegant because it eliminates the need for complex and maintenance-intensive components like hydraulic pumps, oil reservoirs, pistons, or the intricate cable-and-pulley systems found in traction elevators. This fundamental design choice is the root cause of the system’s most significant advantages: fewer points of potential failure, which leads to greater reliability; fewer components to service, resulting in lower maintenance needs; and a compact form factor that requires no separate machine room.

Key Components of a Modern System

A modern screw-driven lift is a highly integrated system where each component is designed for safety, performance, and longevity.

- Threaded Steel Screw: This is the structural backbone of the lift. It is a high-tensile steel rod, precision-engineered with a continuous thread that guides the drive nut. It bears the full weight of the cabin and its occupants.

- Drive Nut: This is the critical moving part, typically made from a durable, low-friction polymer or bronze. It is securely fastened to the lift’s platform structure and is the only component that travels along the screw.

- Electric Motor: Modern systems use advanced, high-efficiency electric motors that provide whisper-quiet and smooth rotation. These motors often incorporate variable frequency drive (VFD) technology to control acceleration and deceleration, preventing any jolts or sudden movements for a comfortable ride.

- Self-Contained Shaft: A defining feature of premium screw-driven lifts is the inclusion of a modular, self-supporting shaft. This prefabricated structure, typically made of powder-coated steel or aviation-grade aluminum with laminated glass panels, is assembled on-site. This completely eliminates the need for a homeowner to undertake costly, dusty, and time-consuming civil works to build a concrete hoistway, a major advantage in retrofitting.

- Safety and Control Systems: A comprehensive suite of safety features is standard. This includes a battery backup system for safe lowering during a power outage, safety sensors or light curtains on the cabin entrance to prevent operation if obstructed, an integrated emergency telephone, and modern, user-friendly control panels both inside the cabin and at each landing

Inherent Safety: Why a Screw-Driven Lift Cannot Free-Fall

The single most compelling feature of this technology is its unparalleled safety, which is engineered into its very mechanics. The system is based on the principle of a “self-locking” screw. The pitch, or the angle of the thread on the screw, is intentionally designed to be very low. This low angle creates a high degree of natural friction between the screw and the drive nut.

This friction is so significant that the downward force of gravity on the fully-loaded cabin is insufficient to cause the nut to slide down the screw on its own. The nut can only move up or down, when it is actively and intentionally rotated by the electric motor. If the motor stops for any reason, whether due to a power cut or a system fault, the nut simply stops in place, held securely by friction. The lift is mechanically locked onto the screw.

See how Cibes designs safe, quiet screw-driven home lifts for real villas. This short video walks you through our products, the self-locking screw technology, and how fast the modular shaft installs. Watch now to understand why Cibes is trusted across the UAE.

This fundamental property makes a catastrophic free-fall event, a common fear associated with elevators, a mechanical impossibility. It provides a level of passive safety that does not rely solely on secondary electronic or hydraulic safety systems. While all reputable lifts sold in the UAE must also be certified to rigorous safety standards like EN 81-41, which mandate additional features like emergency braking systems, the screw-driven design offers a foundational layer of safety that is unmatched.

Screw-Driven vs. Other Home Lifts: A UAE Market Comparison

The UAE home lift market offers several competing technologies, each with distinct advantages and disadvantages. The screw-driven system occupies a strategic “sweet spot,” offering a balanced combination of safety, reliability, and architectural flexibility that is often ideal for the typical luxury villa. It avoids the major drawbacks of traditional hydraulics, is less complex than traction systems, and offers a more substantial feel and greater design freedom than pneumatic lifts. It represents a choice of sensible, long-term luxury.

Table 2: Home Lift Technology Comparison: UAE Context

| Feature | Screw-Driven | Hydraulic | Traction (MRL) | Pneumatic (Vacuum) |

|---|---|---|---|---|

| Mechanism | Motor rotates a nut on a threaded screw. | Fluid is pumped into a cylinder to push a piston. | Ropes/belts and a counterweight move the car. | Air pressure difference moves the cabin in a tube. |

| UAE Competitor Example |

|

|

|

|

| Space Needs | No machine room, minimal or no pit. | Requires machine room for pump and tank. | No machine room, needs more overhead space. | No machine room, no pit. |

| Pros | Inherent safety, reliable, low maintenance, design flexibility, good for retrofits. | Smooth ride, high load capacity. | Energy efficient, faster, quiet. | Futuristic look, fast installation, compact. |

| Cons | Slower speed, limited height. | Higher energy use, potential leaks, regular maintenance. | More complex, higher initial cost. | Limited capacity, can be noisy, plastic feel. |

| Best for... | Existing villas, accessibility upgrades, design-focused projects. | New builds with heavy usage needs. | Taller homes with 4 or more floors where speed matters. | Modernist homes where the tube design is a feature. |

When to Choose a Screw-Driven System

The screw-driven lift is the superior choice under a specific and common set of circumstances for villa owners. You should prioritize this technology if:

- Your primary concerns are uncompromising safety, long-term reliability, and seamless design integration over the raw speed of a commercial elevator.

- Your project is a retrofit into an existing villa, and your goal is to minimize disruptive, dusty, and costly construction work.

- You require a versatile solution for two to four floors that offers extensive customization to match your home’s unique aesthetic.

Understanding Competitors: Nibav (Pneumatic) and Elite Elevators (Hydraulic/Cog-Belt)

To make an informed decision, it is crucial to understand the offerings of key competitors in the UAE market.

- Nibav Lifts: Nibav specializes in pneumatic vacuum elevators, which operate using differences in air pressure within a sealed tube. Their key selling points are the futuristic, 360-degree panoramic polycarbonate cabin and a very fast, clean installation process. The primary trade-offs are a design that is very modern and may not suit classic or traditional interiors, a potentially lower load capacity compared to other systems, and operational noise from the turbines that create the vacuum. The lightweight, polycarbonate construction may also be perceived as less premium than the steel and laminated glass of a screw-driven lift.

- Elite Elevators: As a major player in the UAE, Elite Elevators offers a range of technologies, primarily hydraulic and advanced cog-belt (a form of traction lift), manufactured in Italy by the renowned ThyssenKrupp. Their hydraulic systems are robust and capable of handling heavy loads, making them suitable for high-use scenarios. Their cog-belt lifts represent the high end of the market, offering a faster and quieter ride than screw-driven models, but this performance often comes with a significantly higher initial cost and greater mechanical complexity. For a standard G+1 or G+2 villa, the speed advantage of a cog-belt system may be unnecessary, making the screw-driven lift a more cost-effective and mechanically simpler choice.

Why Cibes Leads in Screw-Driven Home Lifts

Cibes is the leading manufacturer of screw-driven home lifts. It is safe, quiet, and low maintenance. The modular, self-supporting shaft installs fast with a shallow pit and minimal civil work. In the UAE, typical Cibes screw-driven packages for 2–3 stops with standard finishes cost between AED 80,000 and AED 250,000. A factory-direct UAE team provides predictable service and genuine parts.

Safety: Self-locking screw prevents free fall; safe-lowering on power loss

Standards: Built to EN 81-41 with full safety sensors and interlocks

Installation: 0–50 mm pit, ~2.3–2.5 m headroom, 5–10 days for 2–3 stops

Power: 230 V single-phase; efficient daily use

Noise: ~40–60 dB for quiet operation inside homes

Design: Modular shaft fits villas and penthouses; clean finish options

After-sales: Factory-direct UAE support and fast access to parts

FAQs (Frequently Asked Questions) on Screw-Driven Home Lifts

Q: How much space do I need for a screw-driven home lift?

A: You need surprisingly little space. Compact models can be installed in a footprint as small as 1000mm x 1000mm, roughly the size of a small closet. Because they come with their own self-supporting shaft, you don’t need to build thick concrete walls around them, making them highly adaptable to existing home layouts.

Q: Are screw-driven lifts noisy?

A: While older models could be noisy, modern screw-driven lifts are engineered for quiet performance. Premium systems operate at around 40-60 decibels, which is comparable to a quiet conversation or a modern dishwasher. This is achieved through advanced motor technology, sound-dampening materials within the shaft, and the inherently smooth action of the screw-and-nut mechanism itself.

Q: What happens if there is a power outage in my villa?

A: All modern screw-driven lifts sold and installed in the UAE are required by safety standards to have a battery backup system. Cibes, for example, has this feature as standard. In the event of a power cut, this system automatically takes over, providing enough power to lower the lift to the nearest floor and allow passengers to exit safely. The cabin lights and emergency phone will also remain operational on battery power.

Q: How much maintenance does a screw-driven lift require?

A: Screw-driven lifts are known for their low maintenance requirements due to their simple design with very few moving parts. They typically require only one or two service visits per year from a certified technician. This visit involves checking the lubrication system, testing all safety features, and ensuring overall performance, which is generally less frequent and less complex than the maintenance required for many hydraulic systems.

Q: Can a screw-driven lift be installed outside?

A: Yes, many leading manufacturers offer dedicated outdoor models. These lifts are constructed with enhanced, weather-resistant materials, such as galvanized components, weatherproofed electrical systems, and seals designed to withstand the specific challenges of the UAE’s climate, including high heat, humidity, and airborne sand.

Q: What is the lifespan of a screw-driven home lift?

A: With proper, regular maintenance performed by a certified professional, a high-quality screw-driven home lift has a typical operational lifespan of 25 to 30 years. The system’s robust mechanical design and the durability of its core components contribute significantly to its longevity.

Q: Do I need to dig a pit in my floor?

A: In the vast majority of cases, no. This is a primary and defining advantage of modern screw-driven technology. These lifts are specifically designed to be installed directly on top of a finished floor with no pit required. For installations where a perfectly flush entry is desired (e.g., for seamless wheelchair roll-in), a very shallow pit of just 50mm (5 cm) can be created, but the major excavation and concrete work associated with other lift types is completely avoided.

Q: What safety certifications should I look for in the UAE?

A: The most important certification to verify is EN 81-41, which is the key European safety standard governing vertical platform lifts for persons with impaired mobility. This standard is the recognized benchmark in the UAE. Additionally, you must ensure that the installation company is fully licensed by the Dubai Municipality or the relevant local authority in your Emirate, as they will be responsible for conducting the mandatory annual safety inspections.